Soda Ash

Soda ash is a simple, safe, natural compound which has been used in the manufacture of everyday products for thousands of years

Extracted from naturally occurring trona

WE Soda only produces soda ash from naturally occurring trona

Life's invisible ingredient

Soda ash is an essential, but invisible, ingredient in many products which we all use every day

Used in thousands of everyday products worldwide

From glass manufacturing, industrial, and construction, to pharmaceuticals, food and domestic products, soda ash is used in many industries

What is soda ash?

A simple, natural product used in products worldwide

Soda ash is the 10th most consumed inorganic compound in the world, which has been used for over 5,000 years.

It is a safe, simple compound and a key component in a variety of industrial processes from the manufacture of glass to dry powder detergents and lithium-ion batteries. It is also an important ingredient in the food and pharmaceutical industries.

Life's invisible ingredient: Sodium carbonate, Na2CO3

The ancient Egyptians recovered soda ash from dry desert lake beds or produced it by burning marine plants with high sodium content to produce ashes, which gave the commonly used name of 'soda ash'.

They used it to reduce the melting point of silica sand to produce glass vessels and ornaments - the same basic production technique used in glass manufacturing today. The Romans also used its related compound, sodium bicarbonate, for medicinal purposes and to make bread.

Successive generations produced soda ash in this way until the mid-1800s, when synthetic production techniques were first developed, to supply the increasing demand from an industrialising world.

How is soda ash made?

Today, soda ash (sodium carbonate) is produced by two main methods, both of which produce chemically identical soda ash.

Global soda ash demand is expected to continue growing by around 2 million metric tonnes every year, reaching over 80 million mtpa by 2030.

1. Natural soda ash production

Natural soda ash is produced by extracting naturally occurring trona ore and then processing this via a simple process of filtering, concentration, crystallisation and drying into soda ash which can be sold. Today, this accounts for around 30% of global production.

Commercially exploitable trona deposits only occur geologically in three regions of the world: Enormous deposits in Wyoming, USA, large deposits in Türkiye, and much smaller and chemically less pure deposits in China. Today, natural soda ash is only produced in Wyoming, USA and Türkiye.

2. Synthetic soda ash production

Synthetic soda ash is produced using a chemical production process using either the so-called Solvay or Hou method, in which salt (sodium chloride) is reacted with limestone (calcium carbonate) and coking coal in the presence of ammonia to produce synthetic soda ash.

Synthetic soda ash accounts for about 70% of global production, and is a more costly and a far more energy and water intensive production process than natural production methods.

WE Soda only produces soda ash from naturally occurring trona.

Where is soda ash (trona) found?

Natural soda ash has been found in lake brines or naturally occurring mineral deposits. Trona (a mix of water, sodium bicarbonate, sodium carbonate and sometimes sodium chloride or salt) is the most common and richest source of naturally occurring soda ash.

While trona occurs naturally in a few locations worldwide, the largest and purest deposits are found near Green River, Wyoming, USA and near Ankara, Türkiye. To date, these are the only commercially exploitable deposits that have been discovered globally.

We are proud to supply the world with high quality, natural soda ash, manufactured in an environmentally sustainable way, which has earned us green product certification.

How we extract trona ore

First developed at Eti Soda, we are the only company outside China to use innovative solution extraction technology on a commercial scale.

We use this at both our Eti and Kazan facilities. This patented production method injects heated water into the underground ore body, which then dissolves the trona forming brine solution. The brine is then brought to the surface, and pumped to a central processing facility.

This closed loop system is safer (no underground operatives), has minimal impact on the surface, uses significantly less energy and water than other production methods and also produces significantly less CO2 emissions.

How we produce soda ash

Although we produce soda ash in enormous quantities, the process steps to manufacture soda ash from brine solution are quite simple.

Soda ash: Life's invisible ingredient

Soda ash is an essential, but invisible, ingredient in many products which we all use every day.

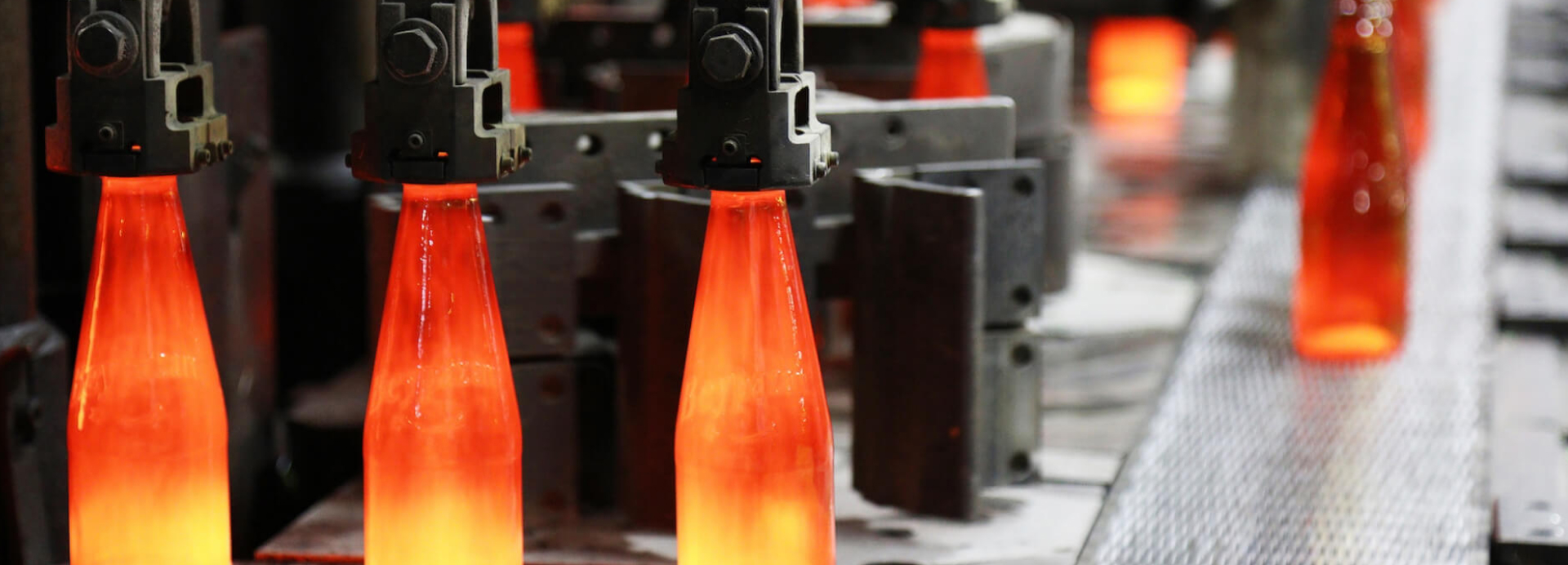

Over half of all soda ash production is used in glass manufacturing, but it is also used in a wide range of other products, such as powdered detergents and soaps and rechargeable batteries, as well as being used extensively in metallurgical processes, and across the food, cosmetic and pharmaceutical industries.

Importantly, soda ash is increasingly being used to improve our environment and reduce polluting emissions by removing sulphur dioxide and other harmful chemicals from exhaust fumes in shipping and other industrial flue gas emissions.

Soda ash: How it is used

When processed, soda ash can vary in density, size and shape. This flexibility allows it to be used in a variety of everyday products. From office building windows to detergents, food manufacturing to internet cables, some common examples are listed below.

Soda ash in everyday use

Soda ash is used in thousands of products we all use every day.

Key soda ash applications

Customer goods & healthcare

Industrial applications

Energy & environment

Agro, feed & food

Building & construction

Sodium bicarbonate

In addition to soda ash, we also produce approximately 400,000 tonnes per year of sodium bicarbonate, also known as “baking soda”, at our facilities in Eti and Kazan.

Like soda ash, sodium bicarbonate is a safe inorganic compound that is chemically closely related to soda ash (aka sodium carbonate).

Uses of sodium bicarbonate

The main uses of sodium bicarbonate are as a raising agent in food manufacture, as an ingredient in pharmaceutical healthcare and animal feed products, and in waste water treatment.

More recently, sodium bicarbonate is increasingly being used in new environmental applications, including the desulphurisation or “scrubbing” of flue gas emissions, particularly in the shipping industry.